Engineering Services

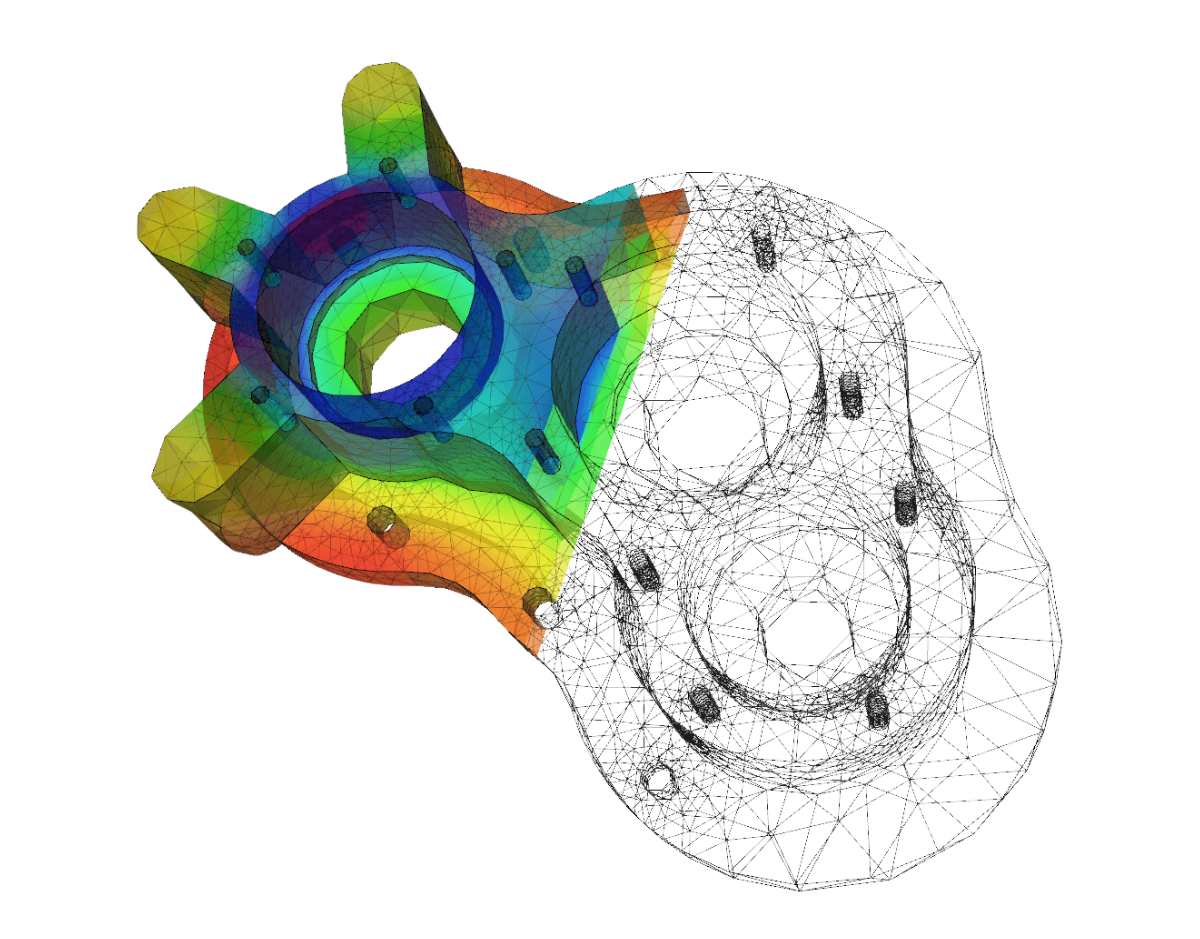

We provide reliable solutions based on the analysis and solid recommendations for improvements. With vast industry experience, our engineers can support any kind of complex analysis requirements that you may have.

Active user

Countries

Total Transactions

ABout Tectorq

We are an Engineering Service company

We Offer a predictive Technological services(CAE) and solutions efficiently and we perform simulation process & expert guidance to help our customers achieve breakthrough results and best product.

- Robust multi disciplinary team with versatile product knowledge

- Over 70000 combined man hours of global CAE/Engineering Design Experience

Meet Our Team

Dr. Tamizh Inian

Founder & CEA Specialist

Dhanush H. Krishnan

FEA Specialist

Arijit Dev M.

R&D Specialist

Dinesh Jose (B.E ,MBA)

Marketing Head

OUR SERVICES - industries we served

Computer Aided Engineering

Services offered by Tectorq

Tectorq Services

- Stress analysis

- Optimization/Weight reduction

- Validation reports as per ASME/EN

- Failure analysis

- Fatigue predictions

- Thermal analysis

- Coupled field problems (Thermal stress)

- Modal/ Natural frequency analysis

- General FEA studies

- Flow analysis Engineering

- Mesh generation of complex parts

- Full Vehicle Integration

- CAE Crash and Safety

- Seat Structure Evaluation

- Luggage Retention

- Full Vehicle High Speed Side Impact Performance and Rear Impact Performance

- EV Battery and Fuel Tank Robustness Evaluation

- Biomechanics

- Non linear analysis

Stress Analysis

Stiffness studies

- Stress check on a valve body- New Product Development team OGES Engineering Bahrain

- Industrial Slurry pump Casing volute profile optimization and wall thickness reconsideration- Pump manufacturer Coimbatore

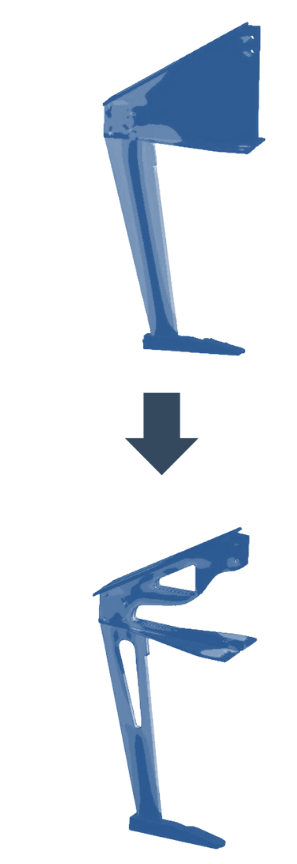

Optimization/ Weight Reduction

Design Improvement

- Toplology Optimization to reduce the weight/maintain the stiffness for Tractor agri-plough.

- Tamil Nadu Agricultural University- Lalapettai Trichy.

Data Acquisition Real-time Testing

Test Correlation

Strain gauging and data acquisition for agri plough to get the real-time load data under operation condition and to validate the same with FEM for optimization study

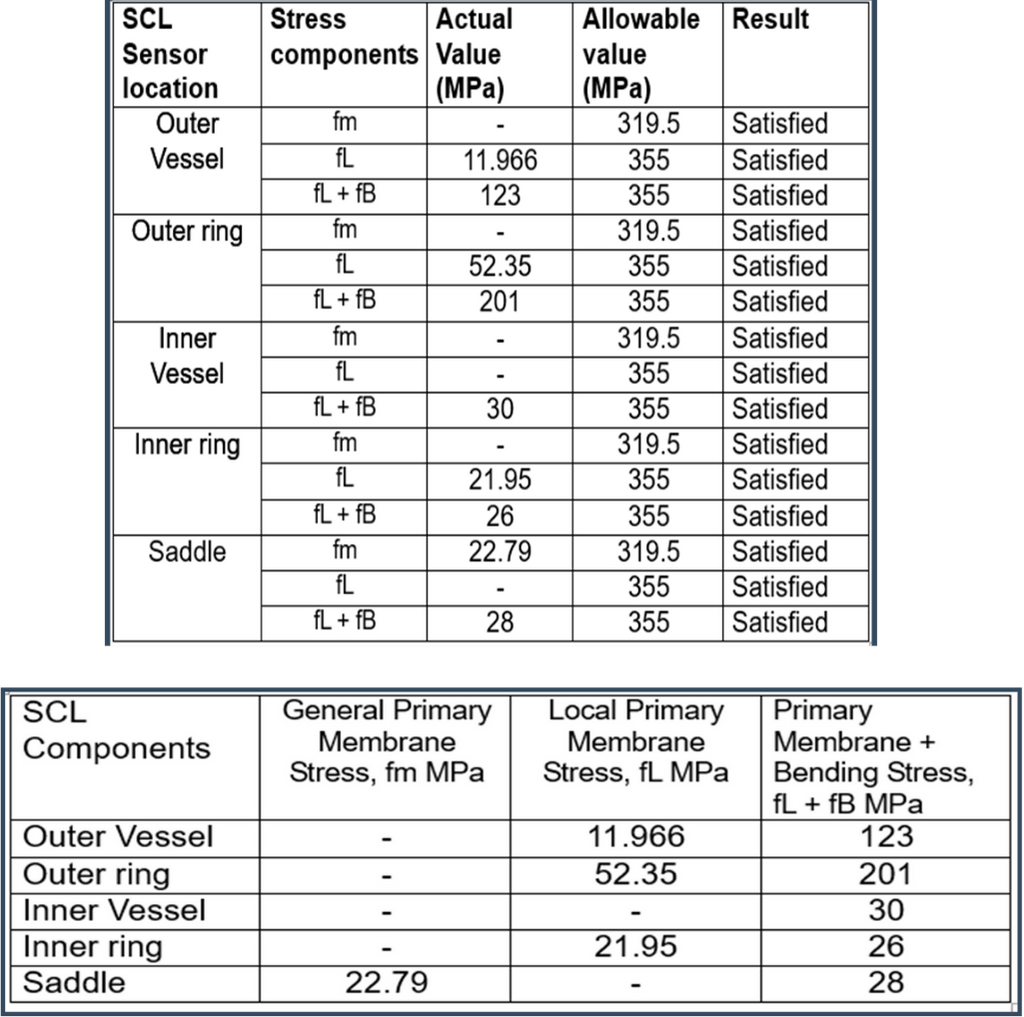

Validation Reports as per ASME/EN

OEM’s & Fabricator’s

- 300 KL Tank – To check the inner vessel , outer vessel and saddle support integrity for the inner and outer pressures, self weight, wind and seismic loads as per EN 13458-2

- Chart Industries -Georgia USA

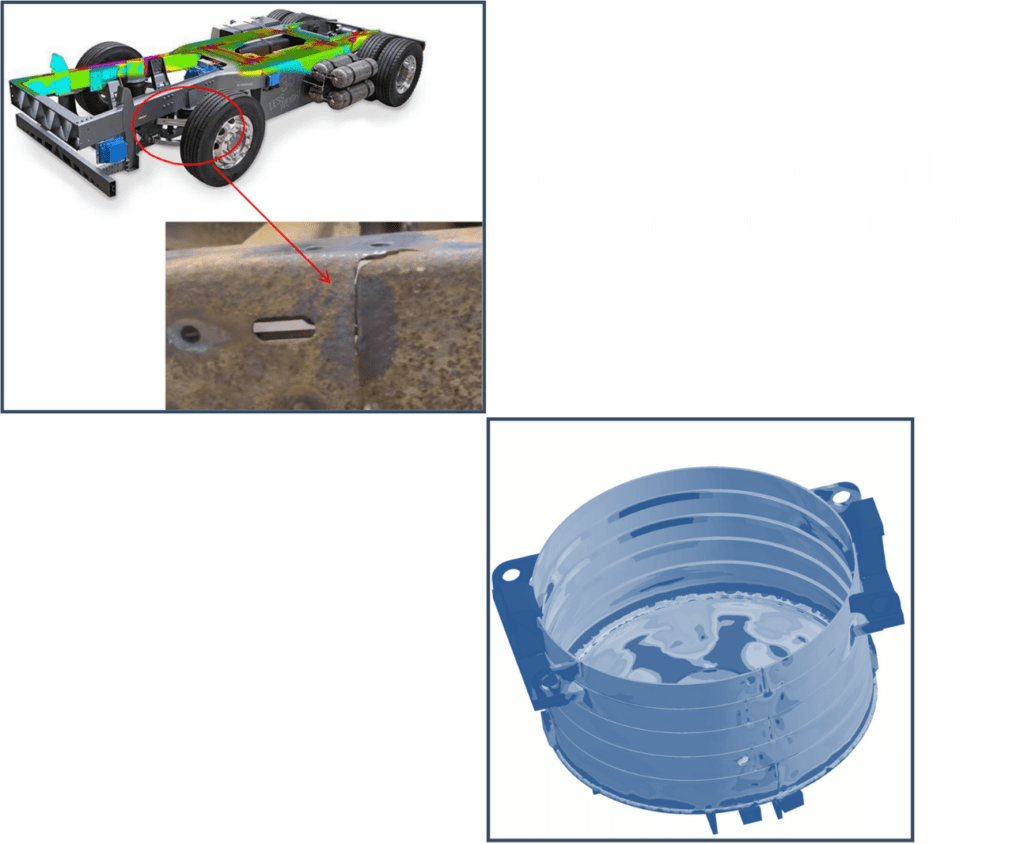

Failure Analysis

OEM’s & Fabricator’s

- Challenge: To address the thickness of the water jacket w.r.t. to the pressure as it is failed for the same

- Outcome: Added stiffness and increased the thickness wherever required

- Customer: PV manufacturer , USA

- Challenge: To analyse the root cause of fatigue failure and improving design against failure

- Outcome: Suggested robust design improvement with simplified geometry completely eradicating the failure, without having any cost impact

- Customer: Leading CV OEM, India

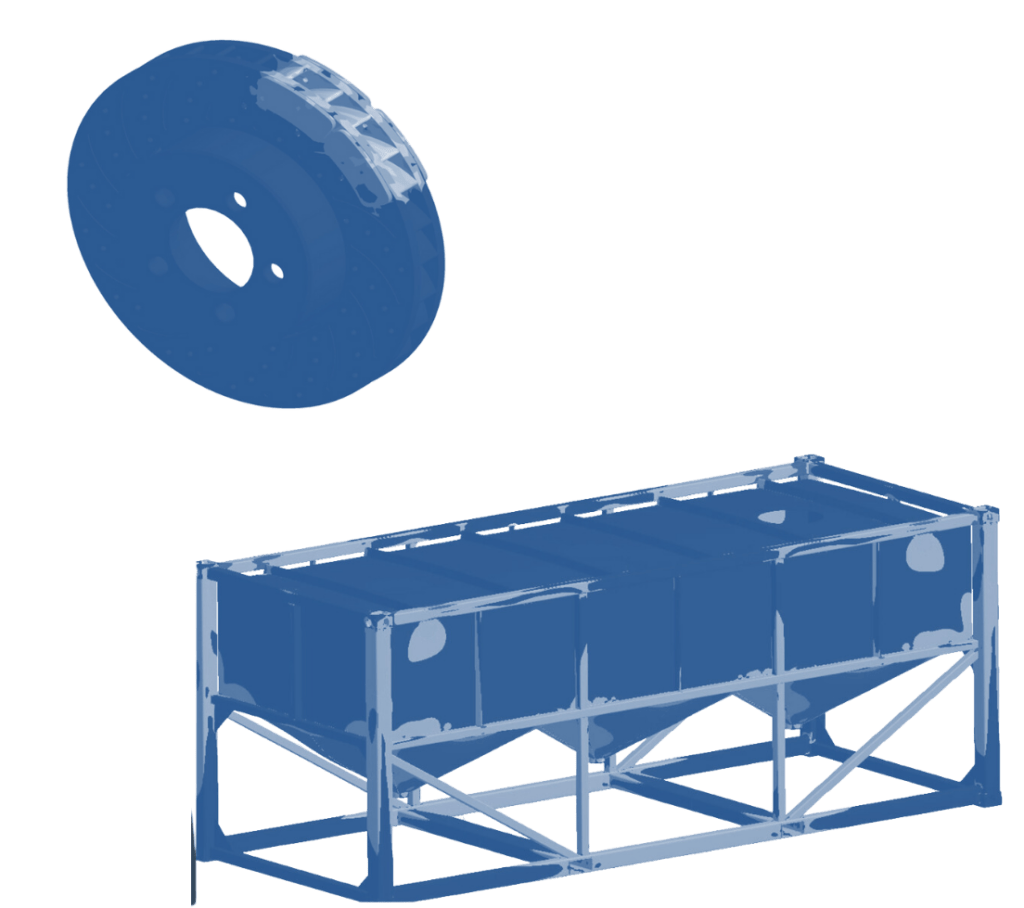

Fatigue Prediction

Durability studies

- Challenge: To check the service life of brake disc

- Outcome: Suggested model for the Brake disc can be used in the market to decrease the thermal fatigue with increased lifetime of the Brake. So in real life scenario, where combined hard and soft braking considered, SS304 disc plates withstands for more thermal fatigue life cycles.

- Customer: SUPRA team, India

Thermal Stress Analysis

Coupled Field Calculations

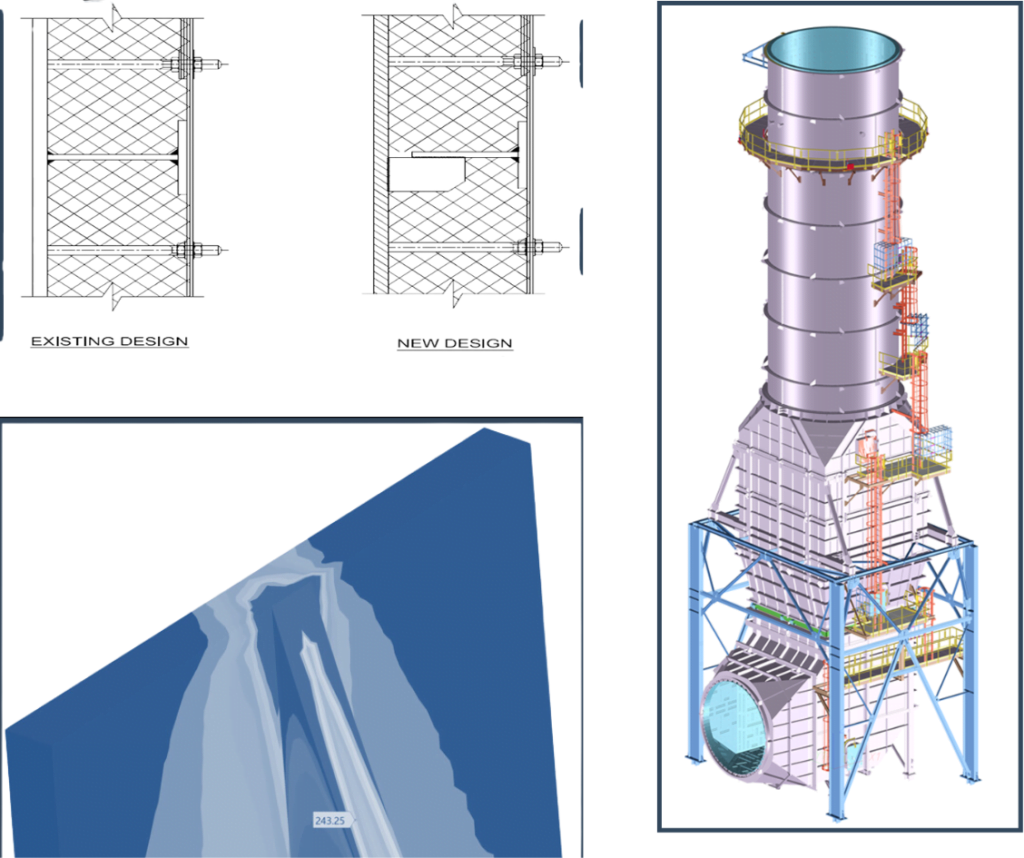

- Challenge: To analyse the structural rigidity of gas turbine exhaust for thermal/buckling/wind/seismic under forced convections

- Outcome: As represented above, we have suggested the design for the optimum thermal gradient.

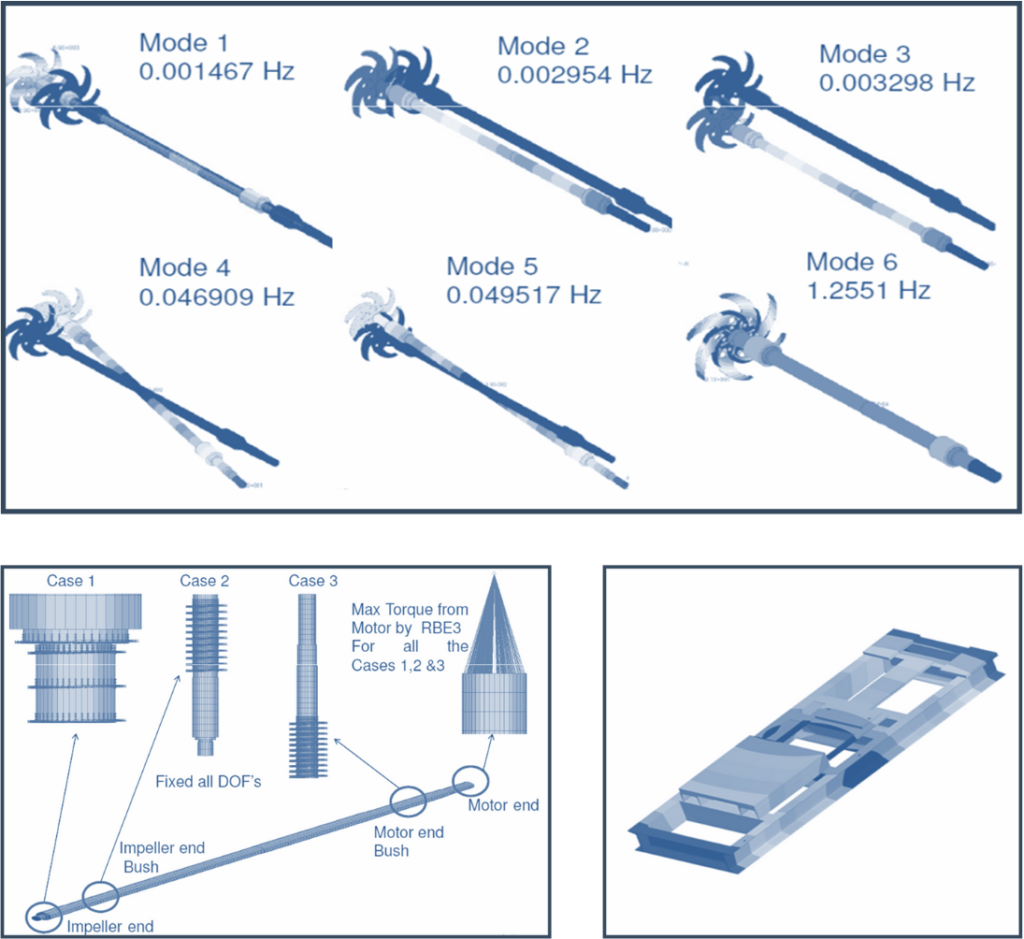

Modal/Natural Frequency Analysis

Dynamic & Damping Studies

- Challenge: To check for resonance with motor frequency of shaft and as well as base plate

- Outcome: It is performed to determine the Shaft assembly vibrational characteristics and corresponding response for finding out Eigen values (Frequencies) and Eigen vectors (Mode shapes)

- Customer: Leading Industrial Pump manufacturer-India

We are an Engineering Service company

Personalized solutions

Crafted for your needs, our solutions are tailored, ensuring precise alignment with your goals and challenges, providing effective results.

Advanced technology

We lead with cutting-edge tech, optimizing processes for efficiency, staying ahead of industry trends, and offering the latest innovations.

Comprehensive reporting

Detailed reports offer a holistic view, empowering informed decision-making and tracking success, ensuring transparency and accountability.

Expert guidance

Navigate complexity with our seasoned professionals, receiving expert advice and insights that guide you through decisions.

Client education

Comprehensive reporting

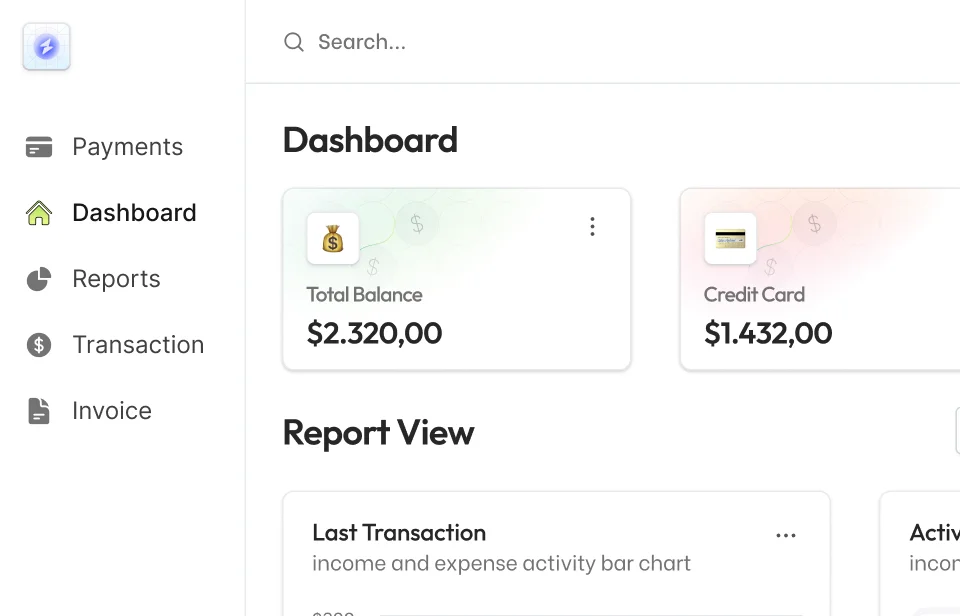

Empowering Your Financial Success Today.

Tax planning

Risk management

Let Us Help You Navigate the Complex World of Finance

We work with you to create customized financial plans tailored to your individual goals and risk tolerance.

Our services include retirement planning, investment management, tax planning, estate planning, and risk management.

Your Financial Potential with Our Expert Solutions

Experience the Confidence that Comes with a Solid Financial Plan

Partner with Us for Expert Financial Planning and Investment Management

Retirement Planning

Advising clients on investment strategies and managing their investment portfolios to help maximize returns.

Tax Planning

Estate Planning

Reduce Costs and Improve Performance.

Optimize Your Designs with Precision. Get a Free FEA Consultation Today!

What Our Clients Say

Paityn Dorwart

Jaydon Bator

James Mango

Frequently Asked Questions

Minimize design flaws and material costs and ensure compliance with industry standards

FEA is a computer-based simulation technique that allows engineers to predict how products will respond to real-world forces, such as vibration, heat, and stress. By using FEA, you can identify design weaknesses, optimize performance, and reduce material costs early in the development process, which helps avoid expensive redesigns and testing later on.

FEA can address a wide range of engineering challenges, including structural analysis (stress, strain, and deformation), thermal analysis (heat transfer), vibration analysis, and fluid dynamics. It’s particularly useful for predicting failure points, assessing material behavior under load, and ensuring designs meet safety and compliance standards.

The accuracy of FEA simulations depends on the quality of input data, the complexity of the model, and the expertise of the engineers performing the analysis. Our team ensures high accuracy by using advanced simulation tools, rigorous validation techniques, and real-world testing to confirm results. While no simulation is 100% perfect, FEA provides reliable insights to guide design decisions.

FEA is widely used across multiple industries, including automotive, aerospace, manufacturing, consumer products, electronics, energy, and medical devices. Any industry that requires precision in design, safety, or performance can benefit from FEA to optimize their products and reduce risk.

The timeline for an FEA project depends on the complexity of the analysis and the size of the model. Simple simulations can be completed in a few days, while more complex models may take several weeks. We work closely with clients to provide accurate time estimates and ensure deadlines are met without compromising quality.